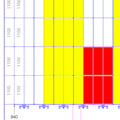

The sloped design of Kanban storage serves two important functions. Firstly, it makes accessing items or components stored within semi-open boxes on the shelves simple. Items are much easier to identify and pick in tilted boxes as opposed to when they are on lying on flat shelving, which will increase workplace productivity significantly as a consequence.

Secondly, the concept of Kanban was first developed to make identifying when items, components or parts needed for production require removal or replenishment. Our Kanban shelves are no exception and make it easy to identify when stocks of a particular item are running low so they can be replenished, eliminating any time that would be wasted if stocks were allowed to run down completely.

The Kanban Steel Storage System is made up of 7 robust, chipboard shelves, 5 of which are tilted to provide easy access to parts. Each shelf is 15mm thick, which ensures they are able to withstand heavy loads. In fact, each Kanban bay forms a strong, sturdy unit that can handle loads of up to 2.5 tonnes when evenly distributed. Every standard Kanban bay is also delivered with 60 TC3 pick bins, although you are able to choose a variety of sizes or colours to suit your unique requirements. Each pick bin is made from polypropylene, a robust, practically unbreakable and fade-resistant plastic that lasts and lasts.

Plus, when purchasing a Kanban storage system from ShelvingDirect, you will be getting a product made from 100% high quality, British manufactured steel. This gives shelving that you purchase from us the edge over cheaper imports that you may see sold elsewhere. All these features ensure that your shelving will stand up to the test of time and last for years to come. This is in a package that boasts straightforward, boltless assembly, meaning your Kanban storage can be ready for use in next to no time.

4 Items